I’m an Electrical and Software Engineer with a robust career at Stanley Black & Decker, where I’ve served as Firmware Lead Project Engineer and Electrical/Software Engineering Manager. I’ve worked on firmware development for DeWalt products like 20V cordless nailers, lighting solutions, and expansion tools, including MEP tools and radios, specializing in BLDC motor controls, Li-ion battery management, test equipment, and BLE connectivity. Leading a team of nine, I’ve driven product launches, managed design reviews, and delivered production code releases, while also innovating through rapid prototyping and proof-of-concepts for projects like robot vacuums and pneumatic torque control tools. With over 30 patents, I’ve made a lasting mark on product development and innovation at the company.

Firmware Lead Project Engineer for 20V Cordless Nailers

Role:

Firmware support for legacy, existing & future 20V nailers

DeWalt DCN920/930/950 Gen4 Framing

Nailers

- Sensorless BLDC motor controls

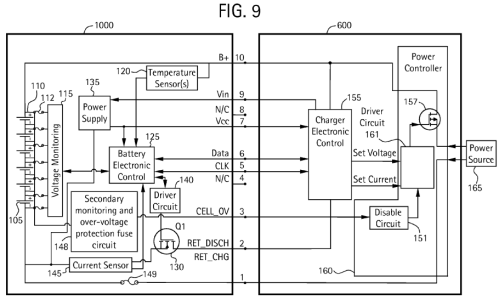

- 20V LiIon battery management

- Production code releases

DeWalt DCN692 Framing Nailer, DCN45

Roofing Nailer, DCN680/DCN660 Finish Nailers, Craftsman CM621

Framing Nailer

- Firmware line maintenance

- Sensored/Sensorless BLDC motor controls

- 20V LiIon battery management

Electrical/Software Engineering Manager for DeWalt Expansion Products

Role:

Lead a group of 9 people (4 EEs, 4 EE Techs, 1 SoftwareEng) to

support DeWalt Expansion Products

DeWalt DCE310, DCE210, DCE600 Gen2 MEP

Tools

- Lead the Software/EE team to final product launch

- Lead team to design production EOL testers

- Nightly Engineering & Sourcing calls with

manufacturer

- Design reviews, safety reviews and DFMEAs

- High level system reviews with cross functional

groups

- IP meetings

- Component reviews and Sourcing strategy

Team Deliverables

- Firmware design

- Electrical design

- Calibration design

- Database design

- Webpage design

- Cloud architecture

- Data privacy adherence

- BLE connectivity strategy

Electrical/Software Engineering Manager for DeWalt Expansion Products

Role:

Lead a group of 9 people (4 EEs, 4 EE Techs, 1 SoftwareEng) to

support DeWalt Expansion Products

DeWalt DCR028, DCR010 and ToughSystem2

Radios

- Firmware support for DCR028 radio

- VI for DCR010 BT radio

- Line maintenance & warranty for ToughSystem2 radio

Lead Project Engineer for DeWalt Expansion Products

Role:

Firmware support for DeWalt lighting products

DCL074 20V/12V Light

- Production code release

- BLE testing and development to phone app

- Design reviews, safety reviews, DFMEA

DCL077 20V/12V Light

- Production code release

- Design reviews, safety reviews, DFMEA

Electrical/Software Engineering Manager for DeWalt Expansion Products

Role:

Lead a group of 9 people (4 EEs, 4 EE Techs, 1 SoftwareEng) to

support DeWalt Expansion Products

DeWalt Wireless Tool Control (WTC)

- Firmware support for remote and

RF receiver in the

DCV585 and DWH161 vacss

- RF compliance testing

- RF error handling algorithms

DeWalt DCV580, DC515 and DWV905 Vacs

- Warranty and reliability analysis

- Supplier QA evaluation

- Line maintenance EE circuit changes

- M class algorithm devleopment and testing for AC vacs

Craftsman 120VAC Jointer

- Waranty and reliability analysis

- Supplier QA evaluation

- Line maintenance EE circuit changes

DeWalt DCE040 BLE Tool Adapter

- Firmware line maintenance support

- Battery coin cell charging and testing

- Current consumption analysis

EE/Software Senior Project Engineer

Role:

Firmware support for DeWalt measurement products

DeWalt DCT419 Wall Scanner

- Rewrote the DCT418 firmware for DCT419

relaunch

- Extensive testing and BT data collection

- Improvements to capacitive sensing algo

- Improvements to the radar processing algo

- Improvements to the ferrous & non-ferrous sensing

algo

- Improvements to the user interface

- Extensive bug fixes

EE/Software Senior Project Engineer

Role:

Firmware and EE Support for DeWalt Innovation Projects

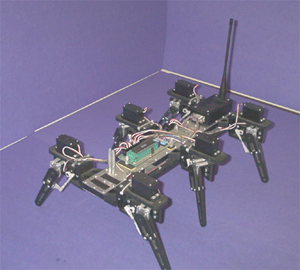

Rapid Prototyping & Proof of Concepts

- Firmware support

- Circuit design support

- VIP demos and presentations

- User field research

- C# PC Software

- C# Smart Phone Software

- Bluetooth

- 3D Tracking Systems

Software Engineer - Project Engineer

Role:

Production firmware for DeWalt NiCad and LiIon Battery Chargers and

Battery Packs. Internal battery cell testing system software.

DeWalt 7.2V to 18V NiCD Chargers

- Production firmware for every

DeWalt NiCad charger

- Engineering test equipment

- Algorithm development

DeWalt 24V Fan Cooled NiCD Chargers

- Production firmware

- Dataloging

- Algorithm development

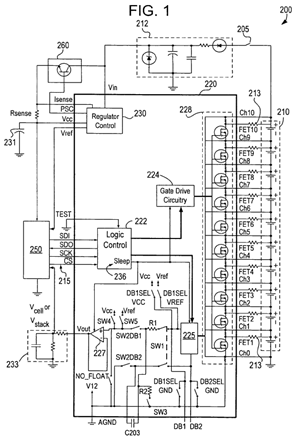

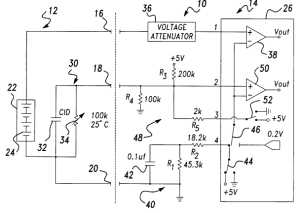

DeWalt 28V/36V LiIon Charger and Battery Pack

- Production charger firmware

- Produciton smart battery firmware

- AFE ASIC specifications

- Algorithm development

DeWalt 18V LiIon Charger and Battery

Pack

- Charger system architecture

- Smart battery system architecture

- Discrete AFE design

DeWalt Battery Cell Test Equipment -

Networked Based

- System architecture

- Visual Basic

- SQL

- HTML, ASP

- Serial comms

- Windows networking

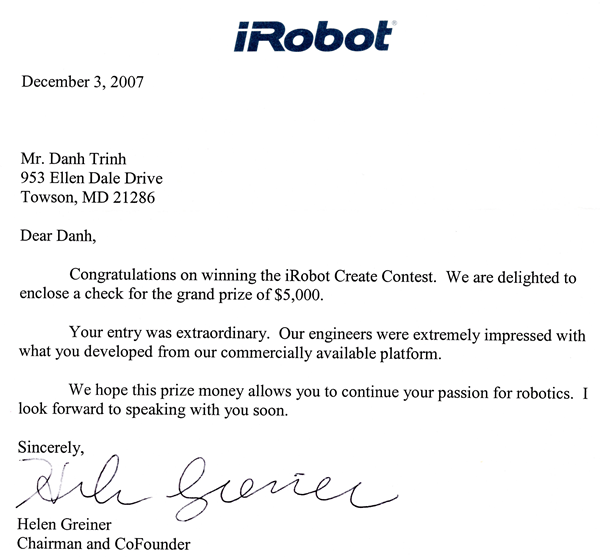

Senior Project Engineer for Consumer Products

Role:

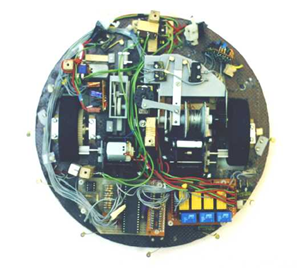

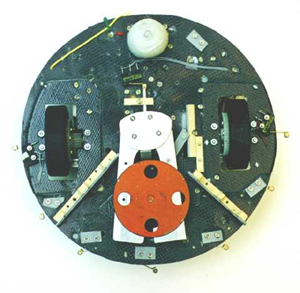

Engineer for Sourced Robot Vacs

B&D SmartTech Robot Vac

- Product specifications

- Competitive teardowns

- Cleaning algorithm evaluations

- Supplier selection

- IP clearance

- International travel to China and UK

Lead Project Engineer for DeWalt Innovations

Role:

EE & Firmware Support for Pneumatic Torque Control

NextGen MacTools Pneumatic Torque

Control

- Torque control algorithms

- IP development

- Tool firmware (DSP, RS422)

- Base station firmware (LCD, keypad, USB host, RS422)

- Tool and base station electronics design